FAQs

General Buying Questions

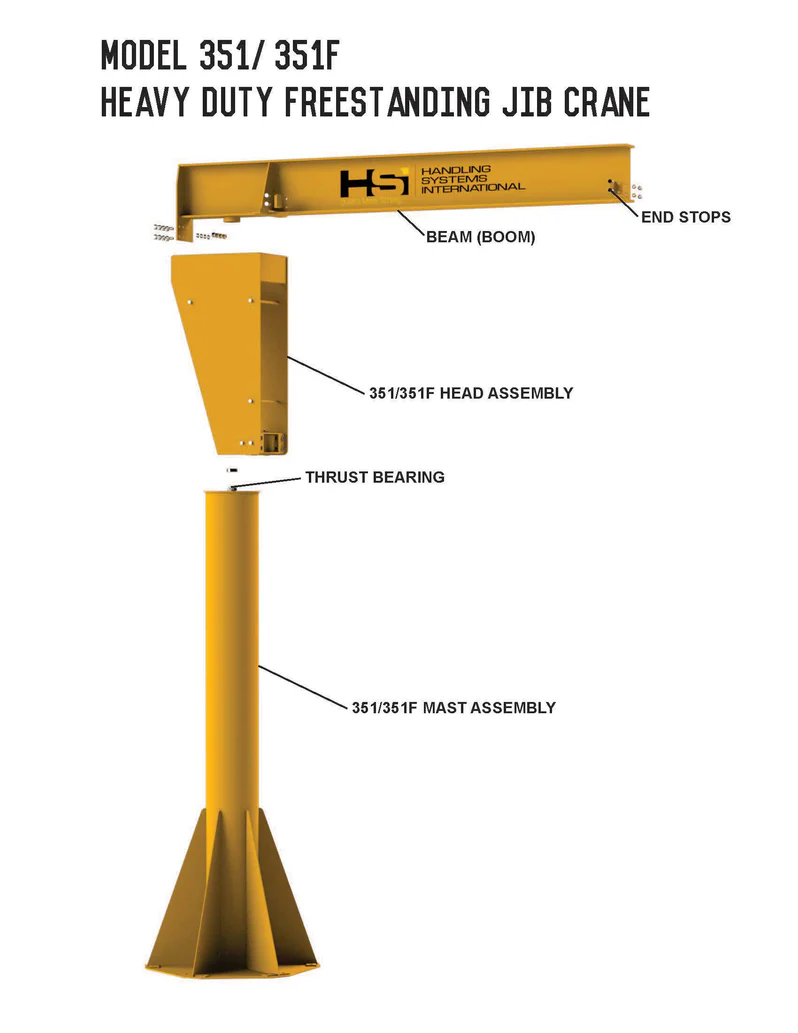

What is a jib crane?

A jib crane is a type of overhead lifting device with a horizontal boom (arm) that supports a load and rotates around a vertical mast. It’s commonly used for localized, repetitive lifting within work cells or specific areas of a facility.

How do I choose the right jib crane for my facility?

Start by identifying your load capacity, lifting height, boom reach, and available space. Also consider whether you’ll mount the crane on a wall, floor, or column, and if your concrete slab can support it. If you’re unsure, our experts can walk you through the best fit for your application.

What are the main types of jib cranes?

- Freestanding

- Wall-mounted (tie-rod or cantilever)

- Mast-mounted

- Foundationless

- Portable or mobile

- Articulating

- Specialty models for harsh or custom environments

What industries use jib cranes?

Industries include aerospace, automotive, manufacturing, marine, mining, warehousing, heavy equipment, and public-sector operations. Jib cranes are ideal wherever precise, repetitive lifting is required.

How much does a jib crane cost?

Costs vary from $1,500 for small foundationless or portable models to $10,000+ for heavy-duty freestanding units. Prices depend on capacity, span, rotation, mounting type, and accessories.

Installation & Mounting

Do jib cranes require a special foundation?

Freestanding cranes typically require a reinforced concrete foundation, designed to support the full load and torque of the crane. However, foundationless models are available for lighter-duty applications and use existing floor slabs.

What is a foundationless jib crane?

It’s a bolt-down jib crane that installs directly onto an existing concrete slab (usually 6–8 inches thick), eliminating the need for a custom foundation. Ideal for leased facilities or quick-install projects.

How much space does a jib crane require?

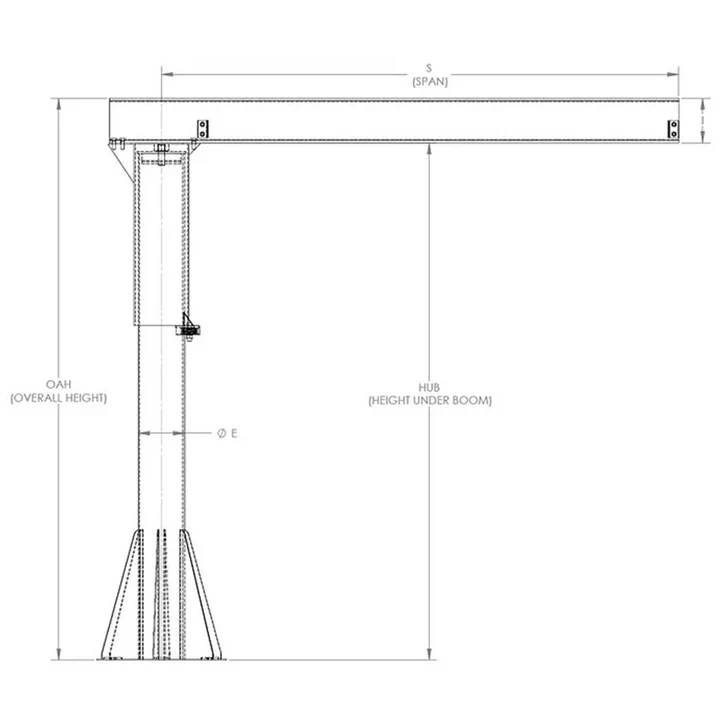

That depends on boom length and rotation range. A 10 ft. boom with 360° rotation requires a 20 ft. clearance diameter. Always account for load overhang and swing area when planning your space.

Can I install a jib crane myself?

Some customers with internal maintenance teams handle their own installs, especially for wall-mounted or bolt-down models. However, professional installation is recommended for foundation-based cranes or high-capacity systems.

Can jib cranes be mounted on walls or columns?

Yes. Wall-mounted jib cranes and tie-rod styles are designed to attach to structural walls or steel columns. It’s important to verify that the mounting surface can handle the moment load.

Crane Features & Operation

What is the typical rotation range of a jib crane?

- Freestanding and mast-mounted: Up to 360°

- Wall-mounted: Up to 180°

- Articulating: Up to 360° on the outer arm, ~200° on the inner arm

What is an articulating jib crane?

An articulating jib crane has two pivoting arms, allowing for flexible, multi-directional movement. It’s ideal for navigating around machinery or placing loads in tight work areas.

What is a telescoping jib crane?

A telescoping jib crane has a boom that extends and retracts in a straight line, similar to a telescope. Unlike an articulating crane, it doesn’t bend at the midpoint—it adjusts reach linearly, often using hydraulic or manual mechanisms. These are used where variable span is needed without changing the crane’s footprint.

How do I determine the right boom length (span)?

Measure how far the load needs to travel from the mast and make sure there’s clearance around workstations, machinery, or walls. Typical spans range from 8 to 20 feet depending on the crane model.

What are typical weight capacities for jib cranes?

Capacities range from 100 lbs for workstation models to 10,000 lbs (5 tons) or more for industrial freestanding units.

Safety, Compliance & Maintenance

Are jib cranes OSHA-compliant?

Yes. All cranes we sell meet or exceed OSHA 1910.179 and ANSI/ASME standards. Always verify proper installation and maintenance to maintain compliance.

Do I need to inspect my jib crane regularly?

Yes. OSHA requires frequent and periodic inspections depending on use. Daily visual checks, monthly mechanical inspections, and annual professional inspections are recommended.

Do jib cranes come with load testing or certification?

Some models include load test documentation. We can also assist with on-site testing or third-party certification after installation if required.

What safety features are available for jib cranes?

Options include rotation stops, overload protection, anti-drop devices, lockout pins, and warning signage. Hoists may include limit switches, thermal protection, and variable-speed controls.

Can a jib crane be used outdoors?

Yes—many models are rated for outdoor use. Look for weather-resistant finishes, stainless hardware, sealed bearings, and base covers. Let us know your environment so we can recommend the right setup.

Accessories & Hoists

What type of hoist should I use with my jib crane?

Choose based on load, duty cycle, and power availability:

- Manual chain hoists for light, occasional use

- Electric hoists for efficient, high-volume lifting

- Air hoists for hazardous or clean environments

Can I add a motorized trolley or rotation to a jib crane?

Yes, depending on the crane model. Powered trolleys and rotation systems are available and are especially helpful in high-cycle or high-capacity applications.

Can I relocate my jib crane later?

- Portable models: Yes—just lift with a forklift

- Foundationless cranes: Yes—unbolt and move

- Foundation-based cranes: Technically yes, but requires cutting/breaking the foundation and reinstalling at a new site

What’s the difference between a jib crane and a gantry crane?

- Jib crane: Fixed to a base, rotates to move loads in an arc

Gantry crane: Mounted on wheels or tracks, moves along the floor to lift over a larger area

Use a jib crane for localized, repetitive lifting; gantry cranes for broader coverage and mobility.

Do you offer specialty or custom jib cranes?

Yes—we can source stainless steel cranes, explosion-proof models, low-headroom configurations, and cranes with unusual spans or mounting conditions. Just let us know what you need.

What’s the lead time for a jib crane order?

Standard models may ship in 2–4 weeks. Custom configurations or large-capacity cranes may take 6–10 weeks. Expedited shipping may be available upon request.