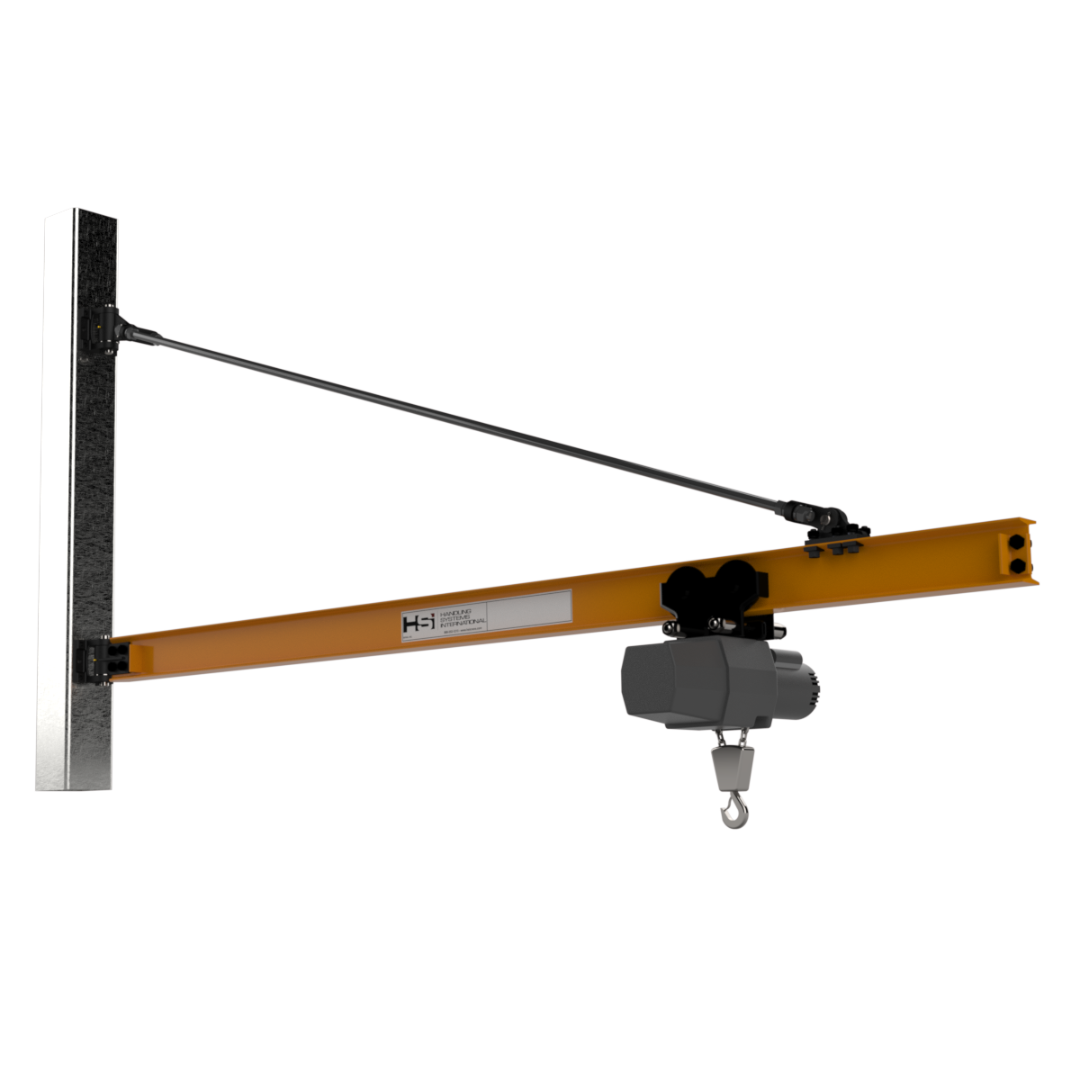

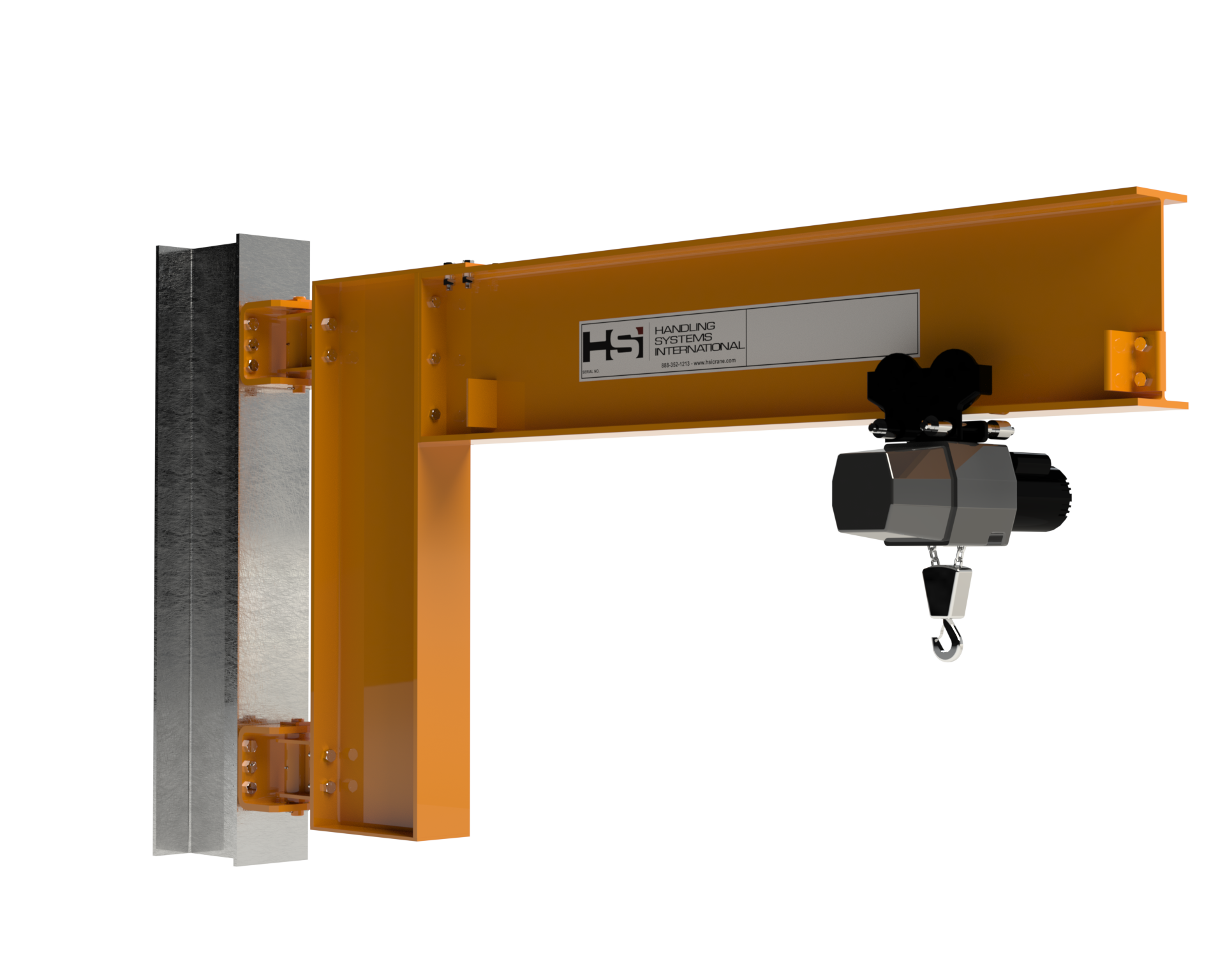

Wall-Mounted Jib Cranes

Optimize Your Workspace with Efficient, Space-Saving Lifting Solutions

Wall-mounted jib cranes are ideal for facilities where floor space is at a premium. By mounting directly to a wall or column, these cranes provide reliable lifting capabilities without occupying valuable floor area. They are perfect for workstations, assembly lines, and maintenance areas where overhead lifting is required but space constraints exist.

Key Features:

- Space Efficiency: Eliminates the need for floor-mounted supports, freeing up workspace.

- Versatility: Suitable for various applications, including manufacturing, warehousing, and maintenance.

- Ease of Installation: Can be mounted to existing structural supports with minimal modifications.

- Range of Motion: Provides up to 180° of rotation for comprehensive coverage of the work area.

Applications:

- Manufacturing Facilities: For lifting and positioning parts during assembly processes.

- Warehouses: To assist in loading and unloading goods.

- Maintenance Areas: For handling heavy equipment during repair and servicing.

Not Sure Which Style You Need?

| Features | Cantilever Style | Tie Rod Style |

|---|---|---|

| Mounting Type | Wall or structural column | Wall or structural column |

| Support Structure | Full cantilevered beam, no tie rod | Upper tie rod with lower wall bracket |

| Capacity Range | 250 lbs – 10,000 lbs (1/8 Ton – 5 Ton) | 250 lbs – 10,000 lbs (1/8 Ton – 5 Ton) |

| Span Range | 8 ft – 30 ft | 8 ft – 30 ft |

| Rotation | 180° | 180° |

| Clearance / Headroom | Maximum clearance under boom (no tie rod obstruction) | Slightly reduced due to angled tie rod above beam |

| Hook Travel | Full, unobstructed hook travel along the boom | Slight obstruction from tie rod mounting hardware |

| Cost | Slightly higher due to increased steel and bracing needs | More economical design for most capacities |

| Ease of Installation | Requires secure wall or column with higher structural rating | Requires structurally sound wall or column |

| Best For | Applications where maximum hook height is critical (e.g. low ceilings) | Cost-sensitive environments with standard headroom needs |

| Common Applications | Workstations, fabrication bays, tool rooms, precision lifts | Assembly lines, machine shops, maintenance stations |

| Finish Options | Powder-coated or enamel | Powder-coated or enamel |

| Hoist Compatibility | Manual or electric hoists, push or motorized trolleys | Manual or electric hoists, push or motorized trolleys |

If you need assistance in choosing the appropriate crane or have any questions, feel free to contact our experts